Tel : +86-18059296519

Whatsapp : +8618059296519

Email : [email protected]

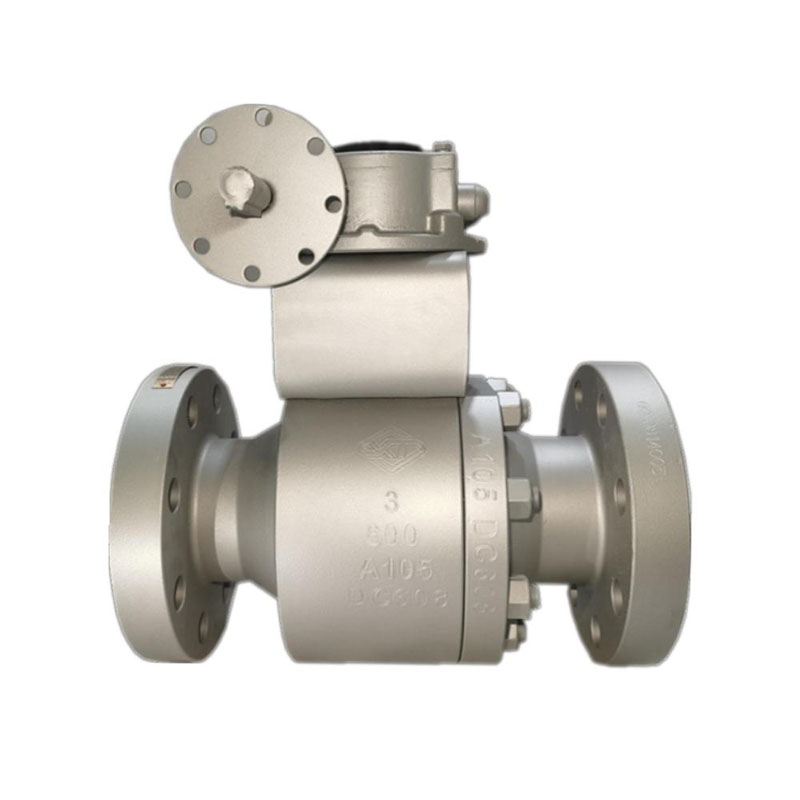

Ball valves is a 90 degree turn type valve, the closure member is a ball which can rotating 90 degree. When the valve is positioned where the bore is aligned in the same direction as the pipeline, the valve is open, and turning the ball by 90 °, then the valve closed.

Size :

DN50 to DN 1200Standard :

API 6D/API 608Material :

A105/A105N, F304, F316, F316L, F51, F53, F55, C95800, UNS N08825, UNS N06625.Pressure :

150LB to 2500LBFace type :

Flanged RF, RTJ, Butt WeldBall valve

Ball valves is a 90 degree turn type valve, the closure member is a ball which can rotating 90 degree. When the valve is positioned where the bore is aligned in the same direction as the pipeline, the valve is open, and turning the ball by 90 °, then the valve closed. There’s a stem and trunnion to fix the ball, and the ball can not move like a floating ball valve, so called trunnion mounted ball valve. Compared with multi-turn valves, ball valves with shorter opening and closing time, longer lifetime, and less space for installation, and the opened or closed state of the valve can be easily detected by position of the handle. Ball valve is widely used in oil & gas, petrochemical, power industries, and usually for on-off application, not suitable for capacity control purpose.

Forged body material, much more stable perfomance than casting body which may have inter defects, since the body is made from forged material, no any repair and the surface looks good. Only solid ball is used to ensure a excellent performance. Compared with floating ball valves, the ball is fixed by both stem and bottom trunnion, so it have lower torque value. When the pressure in the cavity is high, it will push the spring seat move, make it preasure self release. Our trunnion mounted ball valves is strictly designed and produced as per API6D and related standard, 100% tested as per API6D. Painting can be custom appointed as per client requests, such as JOTUN, HEMPEL. TPI is accepted for either process inspection or final dimensional and testing inspection.

Ball valves is a 90 degree turn type valve, the closure member is a ball which can rotating 90 degree. When the valve is positioned where the bore is aligned in the same direction as the pipeline, the valve is open, and turning the ball by 90 °, then the valve closed.

Standard Port Ball Valve, ANSI 150 lbs, Flanged Ends with locking handle.

Standard Port Ball Valve, ANSI 150 lbs, Flanged Ends, Locking Handle, and Direct Mount.

A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball to control flow through it. It is open when the ball’s hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve’s status.

A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball to control flow through it. It is open when the ball’s hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve’s status. Application scope: petroleum chemical industry, electric power, metallurgy, medicine, real estate, municipal engineering and other industries.

A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball to control flow through it. It is open when the ball’s hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve’s status. Application scope: petroleum chemical industry, electric power, metallurgy, medicine, real estate, municipal engineering and other industries.

Cast Steel Trunnion mounted ball valves allow easy and smooth operation at high line pressure. Carefully aligned bearings assist low torque operation. The ball is fixed in position but free to turn. All Casted Trunnion Ball Valves manufactured by Vatac are with reliable high quality castings and fire safe design certified according to BS 6755, API607 & API 6FA. Meet all applicable ASME standards.

Floating Ball Valves are a great choice for on/off service applications in smaller or lower pressure applications because the pressure actually seals the valve. Bonney Forge manufactures Forged Floating Ball Valves in an extensive range of designs, materials, sizes, pressure classes and end connections that are designed in accordance to ASME B16.34 and, where applicable, API 608, API 6D or BS EN ISO 17292. The valves are fire-safe test approved and include design features to ensure electrical continuity between ball, stem and body. Cryogenic and high temperature metal seated configurations are also available. All designs are forged for improved mechanical properties, pressure retention, and quality.

The stainless steel ball valve can be closed tightly with only 90 degrees of rotation and small torque. The completely equal valve body cavity provides low resistance, straight flow channel for the medium. The main feature of the ball valve is its compact structure and easy operation and maintenance. The stainless steel ball valve can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal, and radioactive media. The ball valve body can be integrated or combined. This type of valve should generally be installed horizontally in the pipeline. Stainless steel ball valve classification: stainless steel pneumatic ball valve, stainless steel electric ball valve, stainless steel manual ball valve. Stainless steel ball valve material is divided into 304,316,321 stainless steel ball valves.

A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball to control flow through it. It is open when the ball’s hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve’s status. Application scope: petroleum chemical industry, electric power, metallurgy, medicine, real estate, municipal engineering and other industries.

A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball to control flow through it. It is open when the ball’s hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve’s status. Application scope: petroleum chemical industry, electric power, metallurgy, medicine, real estate, municipal engineering and other industries.

A ball valve is a common piece of industrial equipment that works by allowing fluids to flow through it. The valve’s stem is connected to a manual control mechanism, such as a handle or lever. The stem turns a rotary ball that is attached to a stem that controls how it opens or closes. The valve is also typically controlled by an electric or pneumatic actuator. When used in the manufacturing process, a ball valve can regulate fluid flow by adjusting its float. The ball disc is the third most important pressure boundary inside a ball valve. The disc is made of steel, and in its closed position, the pressure within the media acts against it. Ball valves also have a seat, which can be mounted or suspended. The seat provides a place for the ball disc to rest. Often, a ball valve is made of forged steel and has a seat attached to it. A ball valve can be used in industries where sanitation is very important. A ball valve that can withstand a high level of sanitization is especially valuable in the bioprocessing, food, and pharmaceutical industries. They can handle both liquids and solids. If the fluid contains solids or fibrous material, a ball valve can handle both.

A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball to control flow through it. It is open when the ball’s hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve’s status Application scope: petroleum chemical industry, electric power, metallurgy, medicine, real estate, municipal engineering and other industries.

A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball to control flow through it. It is open when the ball’s hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve’s status. Application scope: petroleum chemical industry, electric power, metallurgy, medicine, real estate, municipal engineering and other industries.

A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball to control flow through it. It is open when the ball’s hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve’s status Application scope: petroleum chemical industry, electric power, metallurgy, medicine, real estate, municipal engineering and other industries.

A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball to control flow through it. It is open when the ball’s hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve’s status.

The flange ball valve refers to a ball valve made of the flange material. The ball valve is a widely used new type of valve. The ball valve is mainly used to cut off, distribute and change the flow direction of the medium in the pipeline. It only needs to be operated with a 90-degree rotation and a small turning torque to close tightly.

Ball valves are available in many variants. One such popular type of ball valve is a 3-way ball valve. The most basic way a three-way ball valve operates is by rotating the ball within the valve body. This rotation aligns the channels of the valve ball with the outlets and inlets. The ball valve stem can be rotated a quarter turn to open or close the bore. The handle has positioned either perpendicular or parallel to the pipe. This position helps the user visualize the status of the valve. Some valves are also designed for automatic shutoffs. This allows them to control valve operation remotely or through a controller. A three-way ball valve can send fluid one way, shut off a flow completely, or mix two different flows. The three-way ball valve is commonly manufactured in T or L-port shapes. Both shapes can be connected to one inlet or outlet, to a single port, or both.

The L port allows one flow to go through one port and the other two to go through the other. Depending on the flow requirements of the application, you can choose between an L port and a T port ball valve. A typical L port ball valve has three ports and an L shape. These valves operate as a diverter without a cut-off position. When the center port is turned an additional 90 or 180 degrees, the valve can be shut off. These valves are often referred to as three-position valves.

A ball valve is a form of quarter-turn valve which uses a hollow, perforated and pivoting ball to control flow through it. It is open when the ball’s hole is in line with the flow and closed when it is pivoted 90-degrees by the valve handle. The handle lies flat in alignment with the flow when open, and is perpendicular to it when closed, making for easy visual confirmation of the valve’s status Application scope: petroleum chemical industry, electric power, metallurgy, medicine, real estate, municipal engineering and other industries.

No.1633, Binhai Road, Wenzhou Economic Development Zone, Wenzhou, China