Tel : +86-18059296519

Whatsapp : +8618059296519

Email : [email protected]

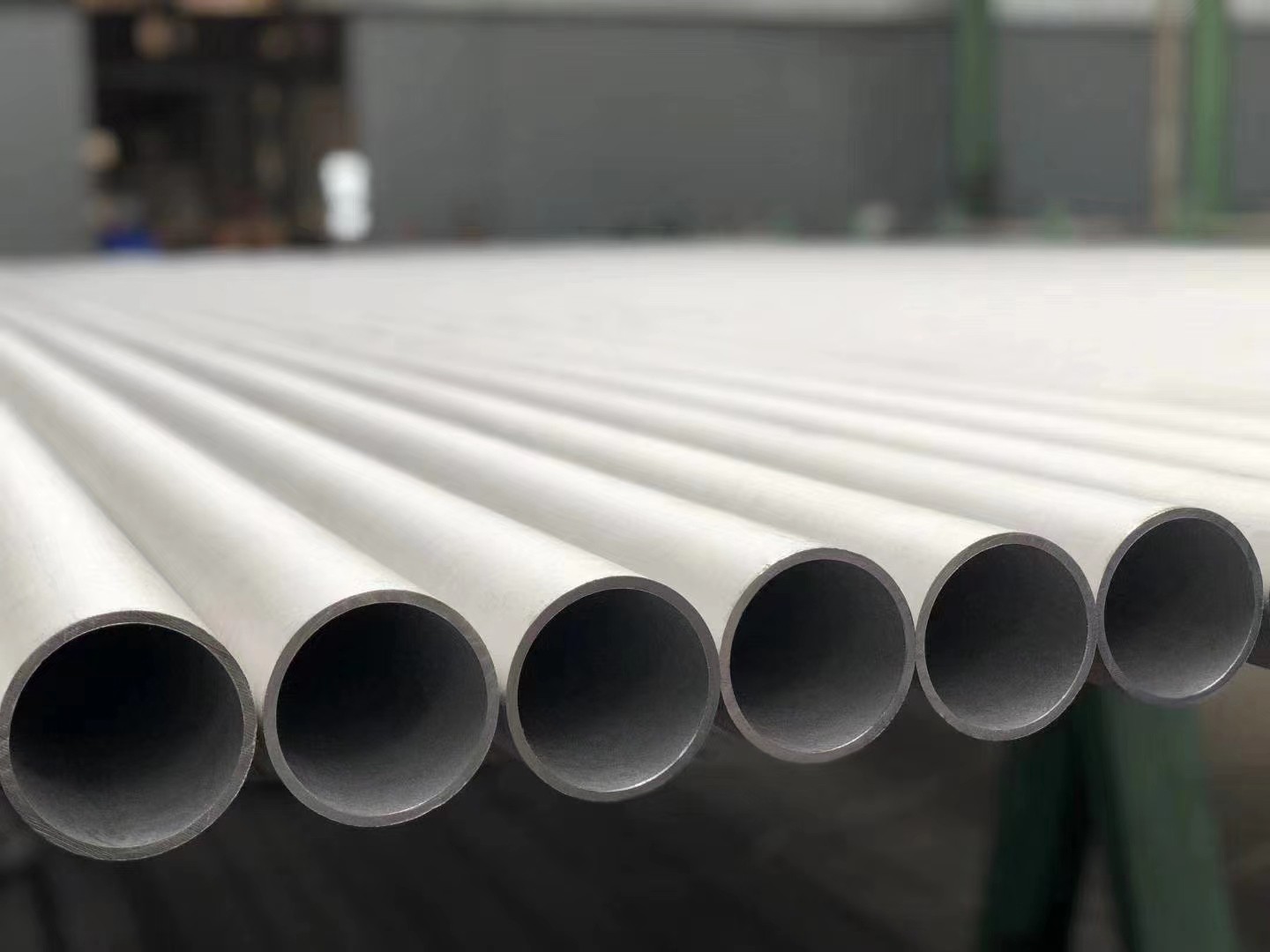

A seamless steel pipe is a circular pipe having a hollow section and no seams around it. The seamless steel pipe is made of carbon steel, alloy steel, stainless steel ingot or solid tube blank, and then is made by hot rolling, cold rolling or cold drawing. Seamless pipes are considered superior to welded pipes as they are built using monolithic steel billets, with intrinsic mechanical strength, without seam welds.

Size :

outer diameter 5-630mmStandard :

GB, JIS, ASTM, DIN, EN, AISIMaterial :

201, 304, 316, 304L, 316L, 321, 904L, etc.Thickness :

0.5-75mmProcess :

hot rolling/cold rollingSeamless Steel Pipe-EC1

Seamless steel pipes have a hollow section and are used in large quantities as pipelines for conveying fluids, such as pipelines for conveying oil, natural gas, gas, water and certain solid materials. Compared with solid steel such as round steel, steel pipe has a lighter weight when the bending and torsion strength is the same, and it is a kind of economical cross-section steel. It is widely used in the manufacture of structural parts and mechanical parts, such as oil drill pipes, automobile transmission shafts, bicycle frames, and steel scaffolding used in construction.

The production of our seamless pipes is tightly regulated and all of the pipes we stock have been fully tested to international standards to ensure we only supply the highest quality products.

Technical data

Seamless Steel Pipe Chemical Composition

This data is a brief summary of the referenced standard. It is informational only and not an official part of the standard; the full text of the standard itself must be referred to for its use and application. ASTM does not give any warranty express or implied or make any representation that the contents of this abstract are accurate, complete or up to date.

|

Standard |

Grade |

Chemical Composition (%) |

Mechanical Properties |

|||||

|

ASTM A53 |

C |

Si |

Mn |

P |

S |

Tensile STrength(Mpa) |

Yield STrength(Mpa) |

|

|

A |

≤0.25 |

- |

≤0.95 |

≤0.05 |

≤0.06 |

≥330 |

≥205 |

|

|

B |

≤0.30 |

- |

≤1.2 |

≤0.05 |

≤0.06 |

≥415 |

≥240 |

|

|

ASTM A106 |

A |

≤0.30 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≥415 |

≥240 |

|

B |

≤0.35 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≥485 |

≥275 |

|

|

ASTM A179 |

A179 |

0.06-0.18 |

- |

0.27-0.63 |

≤0.035 |

≤0.035 |

≥325 |

≥180 |

|

ASTM A192 |

A192 |

0.06-0.18 |

≤0.25 |

0.27-0.63 |

≤0.035 |

≤0.035 |

≥325 |

≥180 |

|

API 5L PSL1 |

A |

0.22 |

- |

0.90 |

0.030 |

0.030 |

≥331 |

≥207 |

|

B |

0.28 |

- |

1.20 |

0.030 |

0.030 |

≥414 |

≥241 |

|

|

X42 |

0.28 |

- |

1.30 |

0.030 |

0.030 |

≥414 |

≥290 |

|

|

X46 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥434 |

≥317 |

|

|

X52 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥455 |

≥359 |

|

|

X56 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥490 |

≥386 |

|

|

X60 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥517 |

≥448 |

|

|

X65 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥531 |

≥448 |

|

|

X70 |

0.28 |

- |

1.40 |

0.030 |

0.030 |

≥565 |

≥483 |

|

|

API 5L PSL2 |

B |

0.24 |

- |

1.20 |

0.025 |

0.015 |

≥414 |

≥241 |

|

X42 |

0.24 |

- |

1.30 |

0.025 |

0.015 |

≥414 |

≥290 |

|

|

X46 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥434 |

≥317 |

|

|

X52 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥455 |

≥359 |

|

|

X56 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥490 |

≥386 |

|

|

X60 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥517 |

≥414 |

|

|

X65 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥531 |

≥448 |

|

|

X70 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥565 |

≥483 |

|

|

X80 |

0.24 |

- |

1.40 |

0.025 |

0.015 |

≥621 |

≥552 |

|

Seamless steel pipe sizes in mm

Out diameter: 1/2 inch - 36 inch (21.3mm-914.4mm)

Thickness: 2.11mm-60mm ( SCH10, SCH20, SCH40, SCH80, STD, SCH120, SCH160, XXS)

Seamless pipe specification chart

| OMINAL PIPE SIZE | OD(mm) | NOMINAL WALL THICKNESS | |||||||||||||

| DN | NB(inch) | ASME | SCH10 | SCH20 | SCH30 | STD | SCH40 | SCH60 | XS | SCH80 | SCH100 | SCH120 | SCH140 | SCH160 | XXS |

| 15 | 1/2" | 21.3 | 2.11 | 2.41 | 2.77 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | |||||

| 20 | 3/4" | 26.7 | 2.11 | 2.41 | 2.87 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | |||||

| 25 | 1" | 33.4 | 2.77 | 2.9 | 3.38 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | |||||

| 32 | 1.1/4" | 42.2 | 2.77 | 2.97 | 3.56 | 3.56 | 4.85 | 4.85 | 6.35 | 9.7 | |||||

| 40 | 1.1/2" | 48.3 | 2.77 | 3.18 | 3.68 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | |||||

| 50 | 2" | 60.3 | 2.77 | 3.18 | 3.91 | 3.91 | 5.54 | 5.54 | 8.74 | 11.07 | |||||

| 65 | 2.1/2" | 73 | 3.05 | 4.78 | 5.16 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | |||||

| 80 | 3" | 88.9 | 3.05 | 4.78 | 5.49 | 5.49 | 7.62 | 7.62 | 11.13 | 15.25 | |||||

| 90 | 3.1/2" | 101.6 | 3.05 | 4.78 | 5.74 | 5.74 | 8.08 | 8.08 | |||||||

| 100 | 4" | 114.3 | 3.05 | 4.78 | 6.02 | 6.02 | 8.56 | 8.56 | 11.13 | 13.49 | 17.12 | ||||

| 125 | 5" | 141.3 | 3.4 | 6.55 | 6.55 | 9.53 | 9.53 | 12.7 | 15.88 | 19.05 | |||||

| 150 | 6" | 168.3 | 3.4 | 7.11 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8" | 219.1 | 3.76 | 6.35 | 7.04 | 8.18 | 8.18 | 10.31 | 12.7 | 12.7 | 15.09 | 18.26 | 20.62 | 23.01 | 22.23 |

| 250 | 10" | 273 | 4.19 | 6.35 | 7.8 | 9.27 | 9.27 | 12.7 | 12.7 | 15.09 | 18.26 | 21.44 | 25.4 | 28.58 | 25.4 |

| 300 | 12" | 323.8 | 4.57 | 6.35 | 8.38 | 9.53 | 10.31 | 14.27 | 12.7 | 17.48 | 21.44 | 25.4 | 28.58 | 33.32 | 25.4 |

| 350 | 14" | 355.6 | 6.35 | 7.92 | 9.53 | 9.53 | 11.13 | 15.09 | 12.7 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16" | 406.4 | 6.35 | 7.92 | 9.53 | 9.53 | 12.7 | 16.66 | 12.7 | 21.44 | 26.19 | 30.96 | 36.53 | 40.19 | |

| 450 | 18" | 457.2 | 6.35 | 7.92 | 11.13 | 9.53 | 14.27 | 19.05 | 12.7 | 23.83 | 39.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20" | 508 | 6.35 | 9.53 | 12.7 | 9.53 | 15.09 | 20.62 | 12.7 | 26.19 | 32.54 | 38.1 | 44.45 | 50.01 | |

| 550 | 22" | 558.8 | 6.35 | 9.53 | 12.7 | 9.53 | 22.23 | 12.7 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24" | 609.6 | 6.35 | 9.53 | 14.27 | 9.53 | 17.48 | 24.61 | 12.7 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26" | 660.4 | 7.92 | 12.7 | 9.53 | 12.7 | |||||||||

| 700 | 28" | 711.2 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | ||||||||

| 750 | 30" | 762 | 7.92 | 12.7 | 15.88 | 9.53 | 12.7 | ||||||||

| 800 | 32" | 812.8 | 7.92 | 12.7 | 15.88 | 9.53 | 17.48 | 12.7 | |||||||

| 850 | 34" | 863.6 | 7.92 | 12.7 | 15.88 | 9.53 | 17.48 | 12.7 | |||||||

| 900 | 36" | 914.4 | 7.92 | 12.7 | 15.88 | 9.53 | 19.05 | 12.7 | |||||||

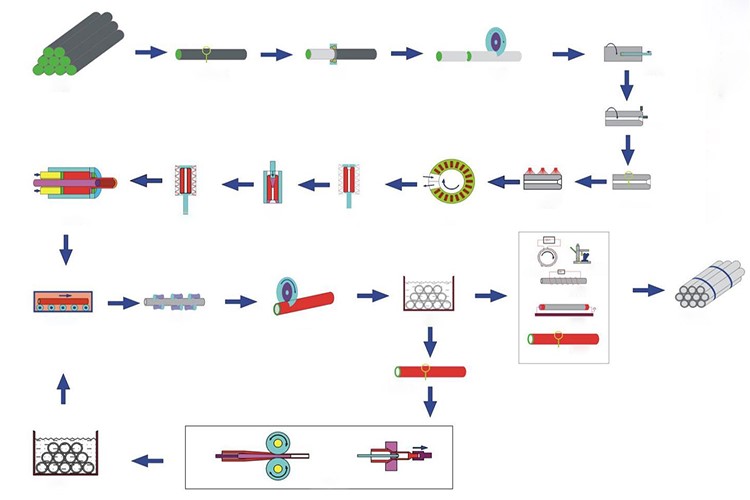

Seamless pipe manufacturing process

1. Seamless Hot Rolling Processes

Round Pipe Billet → Heating → Perforation → Three Roll Skew Rolling, Continuous Rolling or Extrusion → Off Pipe → Sizing (Or Reducing Diameter)→ Cooling → Billet → Straightening → Water Pressure Test ( Or Flaw Detection) → Marking → Storage

2. Seamless Cold Rolling (Cold drawn) Processes

Round Pipe Billet → Heating → Perforation → Head → Annealing → Pickling → Oil (Copper) → Multi Pass Drawing (Cold Rolling) → Billet → Heat Treatment → Straightening → Water Pressure Test → Marking → Storage