Tel : +86-18059296519

Whatsapp : +8618059296519

Email : [email protected]

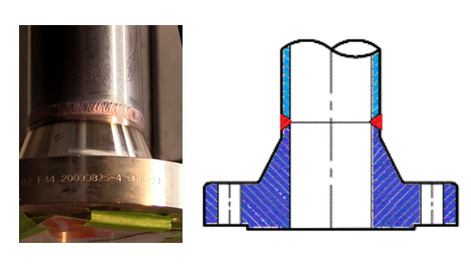

Weld neck flange (WN flange) has a neck and it is designed to transfer stresses to the pipe, thereby reducing high stress concentrations at the base of the flange. It is compatible to the pipelines that works in high or low temperature and bear high pressure. Specially for the pipe or the valves when PN is larger than 2.5 Mpa.

Size :

1/2”-60” Forged FlangeStandard :

ANSI, JIS, DIN, BS,GOSTMaterial :

Stainless Steel (ASTM A182 F304/304L, F316/316L,F321)Pressure :

CLASS 150, CLASS 300, CLASS 600, CLASS 900,CLASS 1500, CLASS 2500,CLASS 3000Face type :

F.F., R.F., R.T.J., M.F., T.G

This kind of flange include lots of specification, Weld neck Flange is expensive because of its long neck and cost of people for contact WN flange with pipeline or fitting but is preferred for high stress applications. The necks, or hubs, transmits stresses to the pipeline.

The weld bevel is attached in a V-joint to the tube end with a similar bevel, which allows for a uniform circular weld around the perimeter for a uniform transition. This allows gas or liquid within the piping assembly to flow through the flange connection with minimal restriction. Check this welded bevel connection after the welding procedure to ensure an even seal and no abnormalities.